BOOM PRODUCTS

急上昇中の商品

NEW

NEW

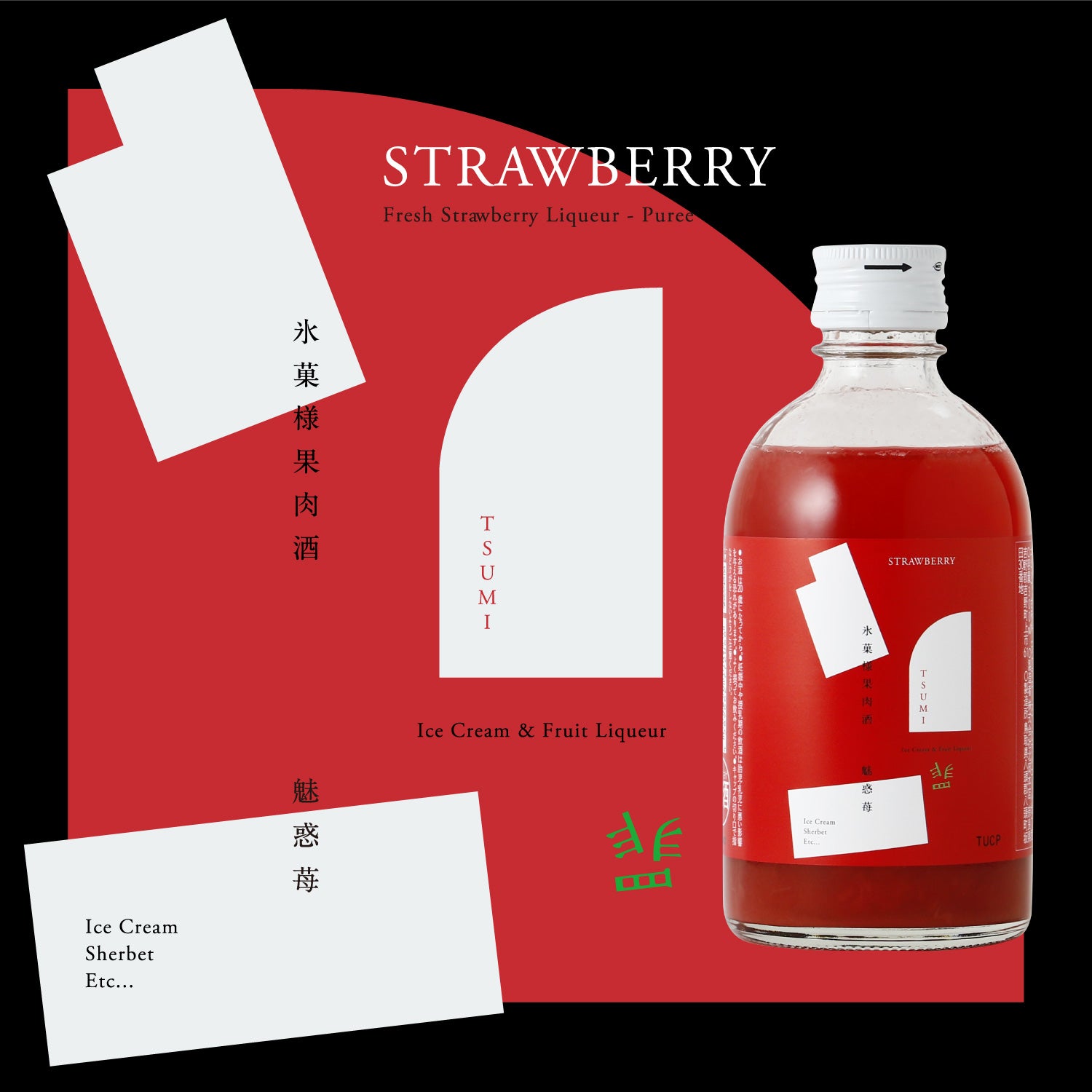

桜と苺と桜桃

NEW

NEW

ねこのさけ -果実酒-

柴犬わいん さくら

NEW

NEW

夜のクラフトコーラ

桜の蜂蜜から、甘やかされちゃう春のミード酒できちゃいました。

女王様のさくらんぼスパークリング

大人のメープルシロップ

NEW

NEW

やんのかステップ

mume Pink

NEW

NEW

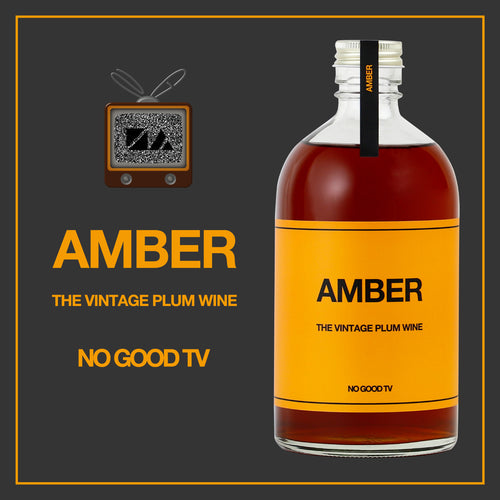

黄金比の梅酒

NEW

NEW

白桃とレモングラス

NEW

NEW

プラネタリウム

大人の喫茶風メロンクリームソーダ

夜9時のチョコミント

BESTSELLER

ベストセラー

NEW PRODUCTS

新商品

届くまでの間もわくわく、届いた後も新たなお酒との出会いを楽しめるクランドの人気コンテンツです!好きな種類のお酒を選ぶことができ、苦手な原料は除外できるので安心。必ずお得に購入できます。中には1本1万円以上の高額な「当たり」のお酒が入ることも……!

定番の酒ガチャ

キーワードで検索

クランドマガジン

食感を楽しむ「夜9時のチョコプリン」振った回数別で変化を比べてみた。

2024.04.17

日本酒でつくるアレンジカクテル

2024.04.12

スタッフのガチ推し酒「大人の喫茶風イチゴクリームソーダ」

2024.04.11

ニュース

-

2024.04.17

クランドオンラインサイトでの「eギフト」サービス一時停止のお知らせ

-

2024.04.10

カスタマーサポート営業時間変更のお知らせ

-

2024.04.04

お支払い方法変更のお知らせ

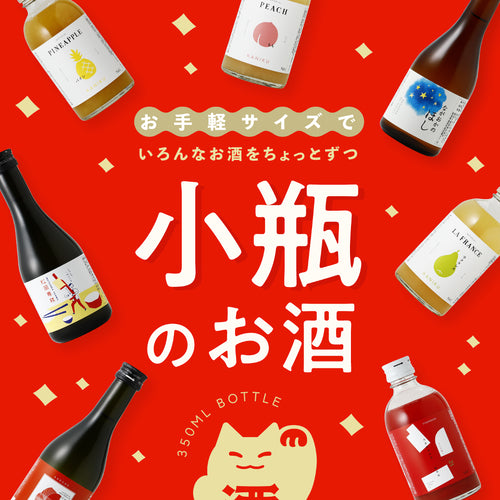

500種類を超える多様なクラフト酒が並ぶオンライン酒屋。

お酒に詳しくない方でも、好奇心の向くままに直感で、

あなたにぴったりのお酒に出会えるお店です。

よくあるご質問

基本的に日時指定は可能です。ご指定がない場合は、通常配送とは異なり、ご注文後、順次発送となります。一部指定できない商品もございますのでご了承ください。

10,000円以上の購入で、基本送料が無料です。地域によって、別途地域別送料がかかる場合がございます。送料について。

可能です。カート内「ギフト梱包を行う」よりご指定ください。なお、一部の商品のみのラッピングはできません。

定番の酒ガチャは、エントリーしやすい5,500円(税込)のプランから季節や期間を問わず販売しています。一方、季節の酒ガチャなどの期間限定の酒ガチャは、割引率アップや1本は好みのお酒を選べるといった特別なプランや抽選キャンペーンなど、その時期に応じてより酒ガチャをお楽しみいただける仕掛けを様々ご用意しております。